- Business Transformation

- Sales & Revenue Optimization

- Finance & Operations

- Information Technology

- Private Equity

- Healthcare & Life Sciences

- High Tech

- Manufacturing

- Explore All Industries →

- Advisory + Diagnostics

- Change Management

- Implementation Services

- Cloud Application Managed Services

- Integrations

- Data Analytics

- Accelerators

- Cloud Applications

- Success Stories

- Insights + Events

- About Us

“A $260 billion ticking time bomb.”

That was CNBC’s view on the implications of retail returns in the reverse logistics cycle in 2016. Since then, buying online has only become easier, with new ways emerging on a seemingly daily basis — which has led to more return processes. Returns are at an all-time high (and increasing), which has companies battling to ensure their customer experience is truly best-in-class — even as they send back products.

Reverse Logistics: More than Just Returns (But a Big Part of the Problem)

While traditional logistics handles everything from creation to consumer, reverse logistics refers to the process in which they work their way backwards, into the hands of the originally producing or selling company. It includes recycling programs, with Apple being a prime example by offering monetary compensation to consumers for trading in their old phone for new; lease returns; delivery failure; repairs and maintenance; unsold goods; and, of course, returns.

For many companies, customer returns are a massive impediment in the process.

These return complexities stress the financial and operational core of a business. Many companies lack accurate financial reporting, operational visibility, and structured workflows to understand the size of the problem and, most importantly, how to lessen it. Even giants like Amazon struggle with this process, often liquidating returns or sending them to waste management facilities, with products in like-new condition. It’s the complicated reality of the quick-and-easy return mentality.

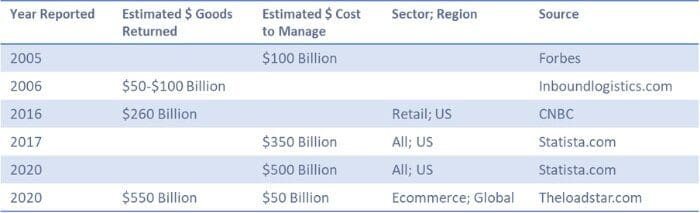

Across the entire manufacturing industry, this difficulty is easy to see, evidenced by the inconsistency in which firms have been able to estimate revenue impacted and associated costs, both at the national and global level.

Circular Economy Through Reverse Logistics

Gartner calls this idea of a circular economy a “closed loop supply chain.” It focuses on sustainability so, rather than disposing of products, they’re repaired, reused, recycled in some capacity, giving them new purpose.

On top of being an environmentally responsible thing to do, utilizing reverse logistics turns waste into value.

By reselling returned goods, either at full or discounted prices depending on condition, effective reverse logistics keeps down any storage and distribution costs. If returned items can’t be resold, can they be reused, recycled, or sold to other companies, either as raw goods or the items themselves?

Asking questions like these can maximize profitability ratios within the supply chain, but it needs to be paired with a smart platform that can plan, manage, and automate reverse logistics to make the absolute most of the situation.

Reverse Logistics & Anaplan

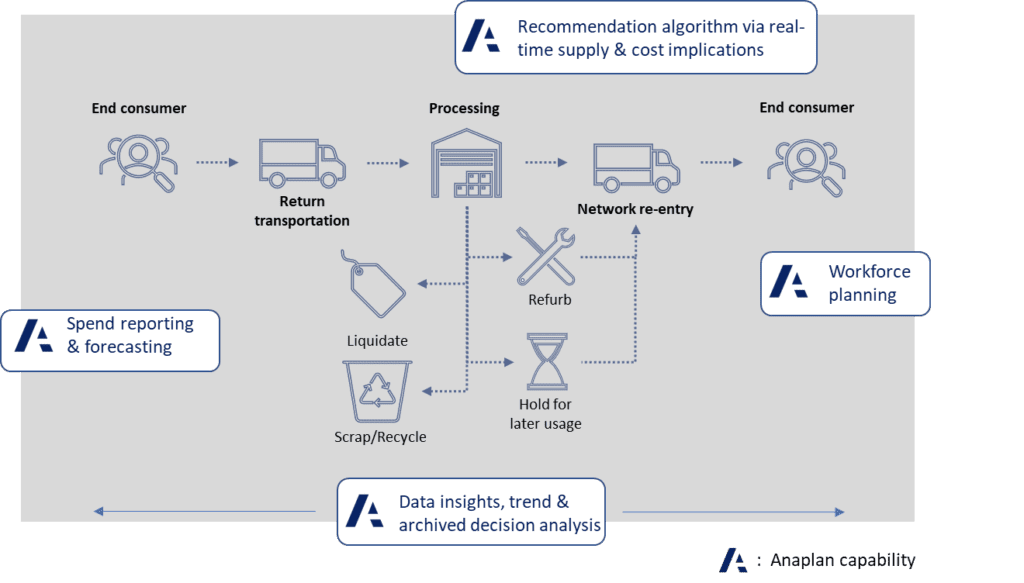

This is where Anaplan can change the game. Does this sound familiar?

- Product success is split between significant demand in one region and stagnant movement in another. Inventory is available, just not in the right part of the country

- Product tied up in returns processing is needed. Without clear visibility to processing lead time and quantity available, an MRP signal is generated for additional ordering

- By the time product arrives from vendor, returned inventory is processed and ready for network re-entry

- The regional inventory shortage has now turned into a national inventory surplus.

- Having a returns-management model that taps into supply, demand, and operations data ensures that the appropriate trade-offs are being considered without requiring native knowledge, manual effort, or wasted time

As a cloud-based platform with a proven track record in the finance, sales, and supply chain planning space, Anaplan can add clarity and structure to the complex web that is reverse logistics.

Anaplan can:

- Consolidate and simplify cross-functional processes and systems.

- Connect processes across functions and data across systems to enable one source of truth within Anaplan, updated in real time based on actions from all business owners, freeing up time for them to make strategic, high-impact decisions instead of repetitive tasks

- Ensure returned inventory is in the right place at the right time

- The algorithm target outcome is flexible and can be based on factors maximizing revenue opportunity, minimizing working capital or network costs, maintaining target supply service targets, or a combination of these. Model inputs can be adjusted by the business and on the fly to fine-tune recommendations specific to business need

- Tighten cost control in returns-management

- Archive past data and decisions made; set targets to inform smart decisions in the future and eliminate end-of- year surprises. What-if scenario plan to understand upstream and downstream

Anaplan Within Your Tech Stack

Anaplan’s flexibility with data sources allows for integration via native connectors, API, or flat file upload, so regardless of source or destination type, Anaplan can consume and send the right information at the desired frequency.

New Anaplan Clients: The reverse logistics model within Anaplan can be a) used as a stand-alone capability, b) integrated with upstream/downstream systems, or c) used as starting point for future implementations in the supply chain, finance, or sales planning space.

Existing Anaplan Clients: Your existing Anaplan financial, forecast, or planning data can connect with the reverse logistics model. Coupled with a supply planning or inventory model, you can optimize how returns are handled between network re-entry, liquidation, later usage, or scrap.

Want to hear from someone mid-process? A Reverse Logistics Manager at a leading online retailer says, “We’re actively working to integrate returns management with our supply plan to enable dynamic repositioning. Connecting the disparate systems has proven to be complex but once we’re able to do so, it’ll be a significant competitive advantage.”

Connect Reverse Logistics to the Rest of Your Supply Chain

With scale comes complexity and as your firm grows, returns-management becomes inherently more complex. A few common routes companies will take as this happens:

- Outsource the reverse logistics operations and management entirely. Spend a premium, take a margin hit, and lose visibility to improvement and integration opportunities that can bolster the backbone of your supply chain

- Continue to manage internally with disparate systems, spreadsheets, and processes. There’s no single source of truth for decision recommendations nor associated snapshots for past, present, and future

You don’t have to fall prey to either of these compromising positions.

Moving forward, Anaplan is the answer.

Customizable, Anaplan can work in parallel with and complement any operations and execution-based enterprise systems – plus, it’s business-owned. As your business scales and adapts, Anaplan has the ability to do the same and do so with limited IT involvement.

Contact Joe Kontak, [email protected], to begin your reverse logistics transformation.