- Business Transformation

- Sales & Revenue Optimization

- Finance & Operations

- Information Technology

- Private Equity

- Healthcare & Life Sciences

- High Tech

- Manufacturing

- Explore All Industries →

- Advisory + Diagnostics

- Change Management

- Implementation Services

- Cloud Application Managed Services

- Integrations

- Data Analytics

- Accelerators

- Cloud Applications

- Success Stories

- Insights + Events

- About Us

Continuous Order Agreements are Significant Challenges for Manufacturing Sales

Not all customer relationship management systems are good fits for manufacturers. While all businesses that sell to customers need basic functions like leads, opportunities, and so on, manufacturers have unique sales challenges to handle, with continuous order agreements (COAs) being a major need that many CRMs don’t meet.

Increasingly, manufacturers are adopting Salesforce Manufacturing Cloud, using the tested CRM capabilities of Salesforce tailored for their specific needs. In many ways this is an easy solution: a purpose-built CRM approach for manufacturing sales. But to maximize the efficiency of your continuous ordering agreements, it can help to use Manufacturing Cloud in conjunction with other solutions.

Continuous Order Agreements Require Integrated Processes

Before we get to the solution, where do the challenges come from? As a Salesforce Summit Partner and Quote to Cash expert, Spaulding Ridge has helped many manufacturers streamline their continuous ordering agreements, bringing sales, engineering, operations, legal, and finance together to provide the full picture. One of the most common problems we see is integrating processes for both large OEMs and Contract Manufacturers.

Building a bill of materials (BOM) or technical drawing is challenging enough—and calculating margin, receiving approval from engineering, and establishing a continuous order agreement adds another layer of complexity. If not managed well, these challenges can lead to lost deals, delayed orders, and significant revenue leakage. In addition, without a unified and rationalized end-to-end solution, forecasting revenue for each customer or distributor that establishes a COA and planning for demand of materials can be an error-prone process.

How to Streamline and Simplify the COA Process

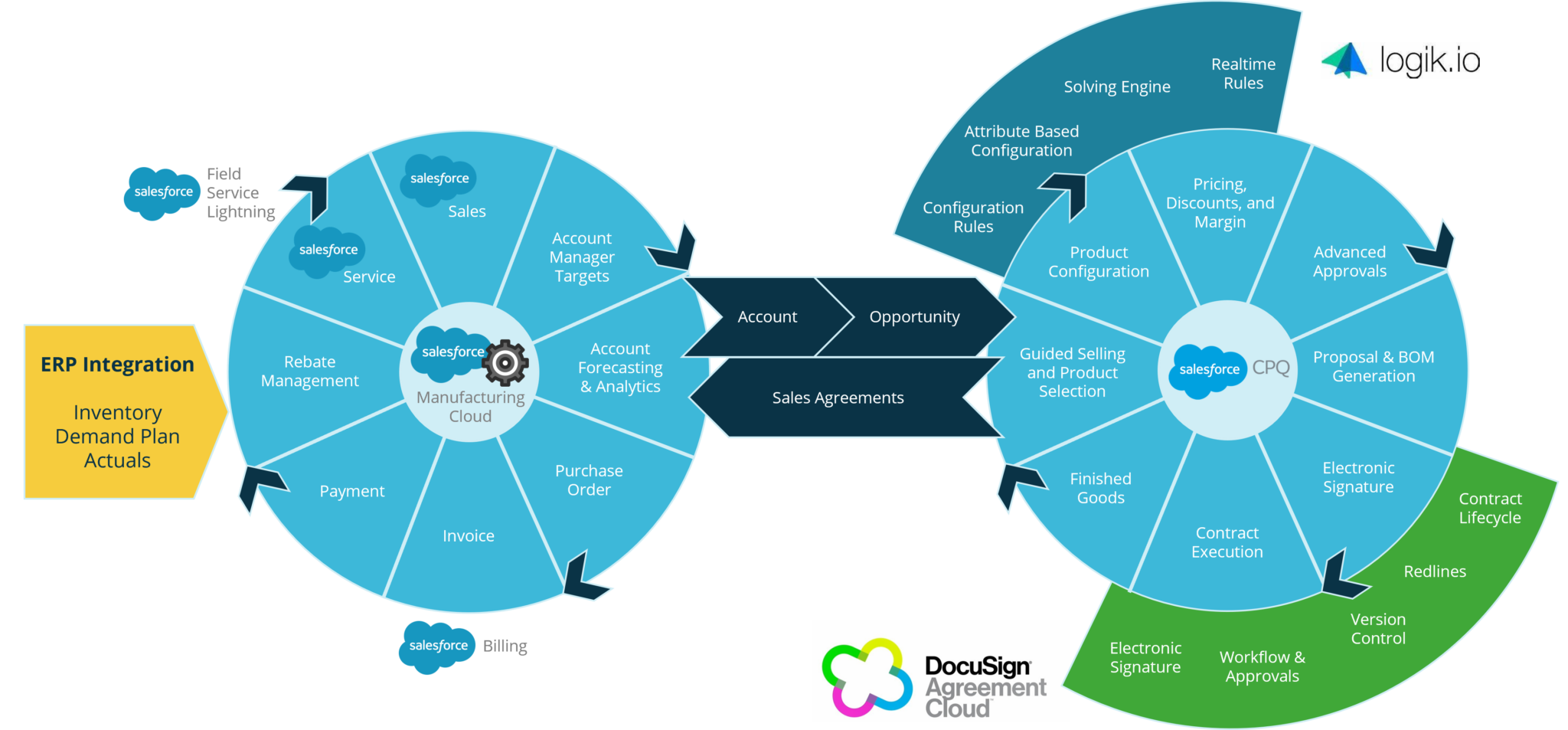

Based on the challenges we see in the market, Spaulding Ridge has established an integrated solution that leverages Salesforce CPQ, Logik.io, and Manufacturing Cloud to support every step of the continuous order agreement process. Here’s how it works:

- Creating a Bill of Materials. The manufacturer creates a list of all the materials and components required to produce the product. This includes raw materials, parts, and sub-assemblies leveraging Logik.io.

- Negotiating with Suppliers. The manufacturer negotiates a continuous order agreement with the suppliers involved. This involves agreeing on the price, delivery schedule, and other terms and conditions and is created via Salesforce CPQ.

- Placing Purchase Orders. Once the agreement is in place, the manufacturer places multiple purchase orders with the supplier for the required materials and components. These purchase orders are based on the BOM and the Scheduling Agreement that is established in Salesforce Manufacturing Cloud.

- Storing and Managing Inventory. The manufacturer stores the materials and components in a warehouse or inventory management system which integrates into Salesforce. This ensures that the required materials are available when needed for production, and that sellers can confirm real-time inventory prior to accepting POs.

- Reordering Materials. As the manufacturer uses the materials and components, they reorder them from the supplier to maintain a continuous supply, referencing the COA and BOM.

- Delivering the Finished Product. Once the product is complete, the manufacturer delivers it to the customer or distributor and tracks the cash flow against the Account Forecast in Manufacturing Cloud.

- Track Performance with Tableau analytics. Segment by markets and products to better plan and invest in the areas of your business that will maximize growth and profitability.

Summing Up: Easier Continuous Ordering Agreements are Possible

By leveraging a connected solution like the one described above, you can bring better insights to sales, operations, and finance, while simultaneously increasing volume and shortening deal cycles for OEMs and contract manufacturers. If you’re having challenges with your COAs, or if you have other questions about enhancing your manufacturing sales process, contact Spaulding Ridge!