- Business Transformation

- Sales & Revenue Optimization

- Finance & Operations

- Information Technology

- Private Equity

- Healthcare & Life Sciences

- High Tech

- Manufacturing

- Explore All Industries →

- Advisory + Diagnostics

- Change Management

- Implementation Services

- Cloud Application Managed Services

- Integrations

- Data Analytics

- Accelerators

- Cloud Applications

- Success Stories

- Insights + Events

- About Us

Nordstrom Inc. is a leading American luxury department store chain that provides apparel, footwear, beauty, and accessory products in person and online.

With ~400 locations and employing over 62,000 people, Nordstrom has an annual revenue of $14.7B.

Before:

Need for End-to-End Inventory Flow Planning Across Their Growing Distribution and Fulfillment Network

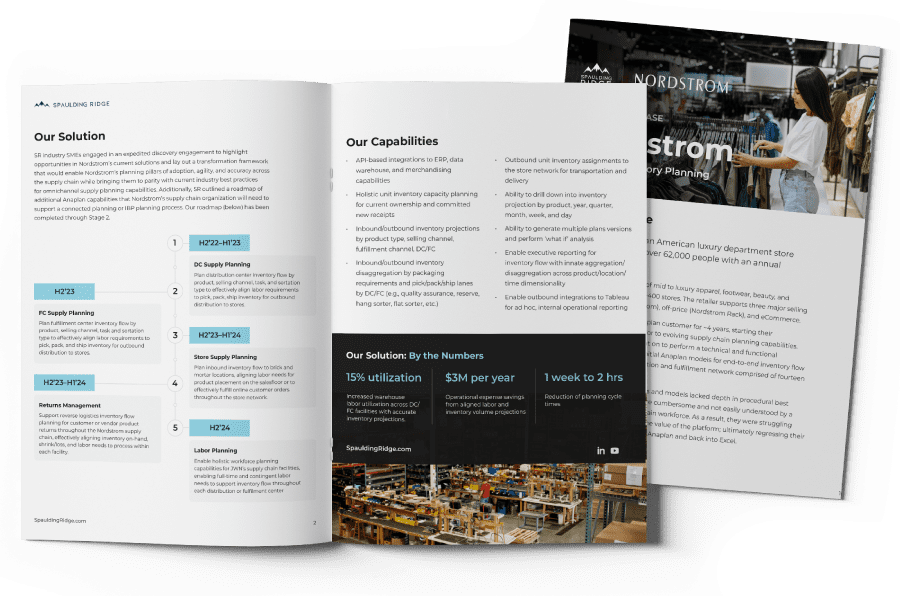

Nordstrom required connected supply chain planning capabilities that could span across their 14 distribution and fulfillment centers. Their existing processes for inventory and supply flow planning were limited in technical capability, creating significant overhead and challenges. They lacked the necessary depth of procedural best practices, and their existing models were too complex and cumbersome for the constantly evolving supply chain. Because of this, Nordstrom struggled with adoption of the platform which limited the full potential of the solution, even reverting to excel spreadsheets in some cases.

Solution:

An Omnichannel Supply Planning Solution with Scalability

The Nordstrom team selected Spaulding Ridge to develop a transformational framework to optimize their supply chain across all their distribution and fulfillment centers. Our team of industry experts created an inventory planning transformation roadmap for Nordstrom focused on ease of adoption, agility, and accuracy, based on industry-leading planning practices, and included a roadmap of additional Anaplan capabilities to support exponential connected planning or IBP process within the supply chain, to comprehensively optimize their supply chain operations within Anaplan.

After:

User-friendly, Efficient, and Accurate Supply Chain Planning

As the solution has taken shape, Nordstrom has seen a major reduction in planning time cycles – from 1 week to 2 hours, generating savings of approximately $3M on operational expenses from aligned labor and inventory projection that yielded a 15% increase in warehouse labor utilization and accuracy.

Want access to the full story?

Download our Client Showcase to learn how Nordstrom boosted efficiency and saved costs with Spaulding Ridge. Access the roadmap to supply chain excellence.